herunterladen

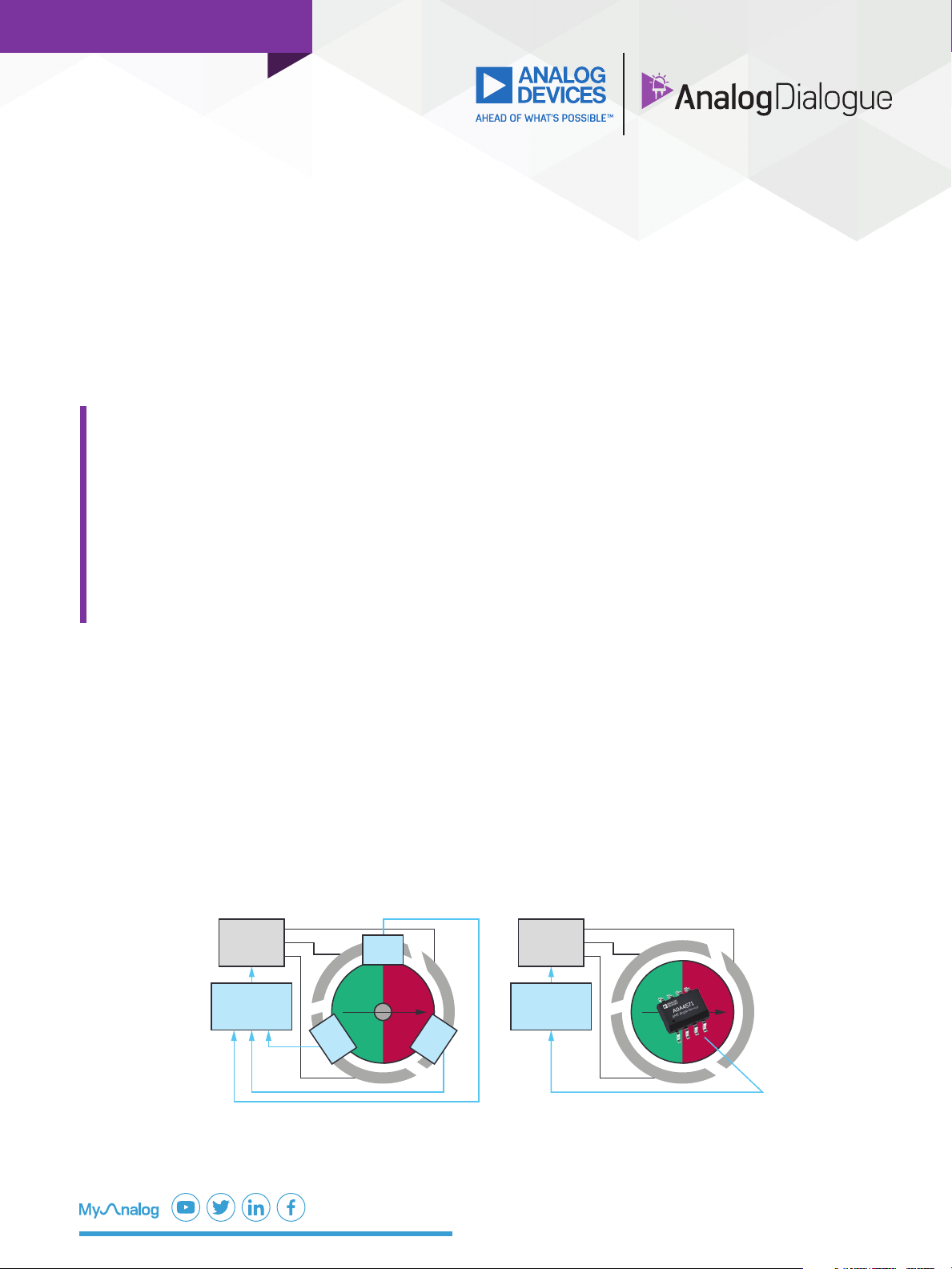

Figure 1. (a) BLDC block commutation control and (b) BLDC sine commutation control.

Gate

Drivers

Gate

Drivers

(a) (b)

Microcontroller

Microcontroller

Hall

Switch

Hall

Switch

Hall

Switch

VISIT ANALOG.COM

Vol 53 No 4, November 2019

Dual AMR Motor Position

Sensor for Safety

Critical Applications

Enda Nicholl , Strategic Marketing Manager

Abstract

This article provides insight into the trends in automotive electri-

fication as we move toward partial and full autonomous driving

and, in particular, the changes required to make electrical power

steering

(

EPS

)

and electrical braking systems meet the necessary

safety standards to ensure the safe and reliable control of driver-

less vehicles.

Analog Devices, Inc.

(

ADI

)

is a provider of magnetoresistive

(

MR

)

position sensor products and shunt-based current sense amplifier

products enabling high performance commutation and safe opera-

tion of brushless motors used in EPS and electrical braking systems.

Introduction

The increased emphasis to improve vehicle safety in recent years has

resulted in the welcome advancement and introduction of active advanced

driver assistance systems

(

ADASs

)

to complement the traditional passive

systems reliant on airbag deployment for driver and passenger safety.

These emerging systems are intended to initially aid—but longer term

replace—the driver’s vehicle maneuver decision making in safety critical

situations. These technology advancements are also leading the way to

the transition to semi- and fully autonomous driving. Replacing the driver’s

decision making with electronic control units

(

ECUs

)

and replacing the

steering and brake maneuvering of the vehicle with actuators is shifting

responsibility away from the driver to the sensors, the ECUs, and the elec-

trical actuators. This trend is leading to the development of more reliable,

intelligent, higher performance, and redundant electrical actuator solutions

that need to comply with the ISO 26262 functional safety standard. This

is a risk-based safety standard, where the risk of hazardous operational

situations is qualitatively assessed, and safety measures are designed into

the components and system to avoid or control systematic failures and to

detect or control random hardware failures or mitigate their effects. These

actuator systems generally use brushless dc

(

BLDC

)

motor drives, and as

these systems are safety critical, the designers must design the solution

hardware and software such that the system complies with the highest

automotive safety integrity level

(

ASIL

)

D.

BLDC Motor Commutation and Control

Brushless dc motors, as the name suggests, have no brush contacts, and

motor position sensors

(

MPSs

)

are needed to measure the relative position

between the stator and rotor to ensure the correct stator coil energizing

sequence. This is particularly critical at startup when there is no back EMF

available and it is impossible for the microcontroller to determine the rela-

tive rotor and stator positions.

Traditionally, block commutation

(

see Figure 1a

)

, which is comprised of

three Hall switches, has been used to indicate the rotor position in BLDC

motors. The demands to improve performance and, in particular, reduce

noise, vibration, and harshness

(

NVH

)

and improve running efficiency of

BLDC motor drives

(

including EPS systems

)

is resulting in a move away from

block commutation to sine commutation control. The Hall switches can be

replaced with an MR angle sensor positioned in front of a bipole magnet

mounted onto the end of the motor shaft

(

see Figure 1b

)

. It is also typical for

the MPS to be mounted onto the ECU assembly and for the ECU to be inte-

grated into the motor casing and positioned at the end of the motor shaft.