herunterladen

AN-638

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

INTRODUCTION

This application note describes the 32-lead ADN2847

laser diode driver Rev. A1 evaluation kit. The evaluation kit

is a demonstration board that provides ac-coupled opti-

cal evaluation of the ADN2847. This document describes

how to congure the board to operate these parts opti-

cally. The document contains the following information:

• Board description

• Quick start for optical operation

• Description of board settings

• Component list

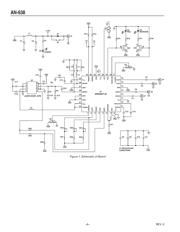

• Schematic of board

• Board layout Information

• Silkscreen image of board

• Optical eyes

BOARD DESCRIPTION

The ADN2847 is a 3 V dual-loop 50 Mbps to 3.3 Gbps laser

diode driver. To use the board in an optical conguration,

a suitable laser diode must be soldered onto the board.

The monitor photodiode (MPD) current is fed into the

ADN2847 to control the average power and extinction

ratio. The ADN2847 uses automatic power control (APC)

to maintain a constant average power over time and tem-

perature. The ADN2847 uses closed-loop extinction ratio

control to allow optimum setting of the extinction ratio for

every device. This board is congured for lasers in mini-

DIL packages only. LEDs for power supply, DEGRADE, and

FAIL are made available for monitoring purposes. Power

to the ADN2847 evaluation circuitry is –3.3 V only.

QUICK START FOR OPTICAL OPERATION

To ensure proper operation in the optical conguration,

verify the following:

1. Jumpers K3 and K4 are connected to A; Jumper K2 is

connected to B.

2. If the input data is clocked, it is necessary to enable

the clock select pin (CLKSEL). CLKSEL is enabled by

connecting K4 to B. If the clock inputs are not used,

or the input data is not latched, connect K4 to A.

ADN2847 AC-Coupled Optical Evaluation Kit

By Mark Murphy, Ferenc Barany, and Michael O’Flanagan

3. The power supply is diode protected to ensure the

device is not damaged if a positive power supply is

accidently connected. The user may connect Jumper

K1 (short circuit) and power up the board by applying

–3.3 V to the power input SMA, J3. If Jumper K1 is not

connected, the user should make the power supply

sufciently negative to ensure that the ADN2847 sup-

ply is –3.3 V. The actual DUT supply can be measured

at the anode of D1.

4. Apply a differential signal, typically 500 mV, to J6 and

J7 (DATAN and DATAP). Single-ended operation may

result in a degraded eye.

5. If the clock select pin is enabled by K4, apply a

differential clock signal, typically 500 mV, to J4 and

J5 (CLKN and CLKP). If the clock pin is not enabled,

a clock signal should not be connected.

6. The optical eye and switching characteristics of the

ADN2847 may be observed using a digital communi-

cations analyzer that has an optical input channel with

the required bandwidth.

7. The bias and modulation currents can also be moni-

tored by observing IBMON and IMMON, respectively.

IBMON and IMMON are both a 1:100 ratio of I

BIAS

and

IMOD. Both are terminated with resistors and so can

be viewed at Test Points T3 and T4 using a voltmeter

or oscilloscope.

8. To establish the desired average power and extinction

ratio, the user should follow this procedure.

a. With the power supply turned off, adjust Potentiom-

eters R20 (ERSET) and R21 (PSET) to approximately

20 k.

b. With the evaluation board powered on and the data

signal switching, the user can reduce the value of

Potentiometer R21 to establish the desired average

optical power.

c. Potentiometer R20 can then be reduced in value

to increase the modulation current and hence

increase the extinction ratio. The bias and modula-

tion currents can be monitored using IBMON and

IMMON.

REV. 0