herunterladen

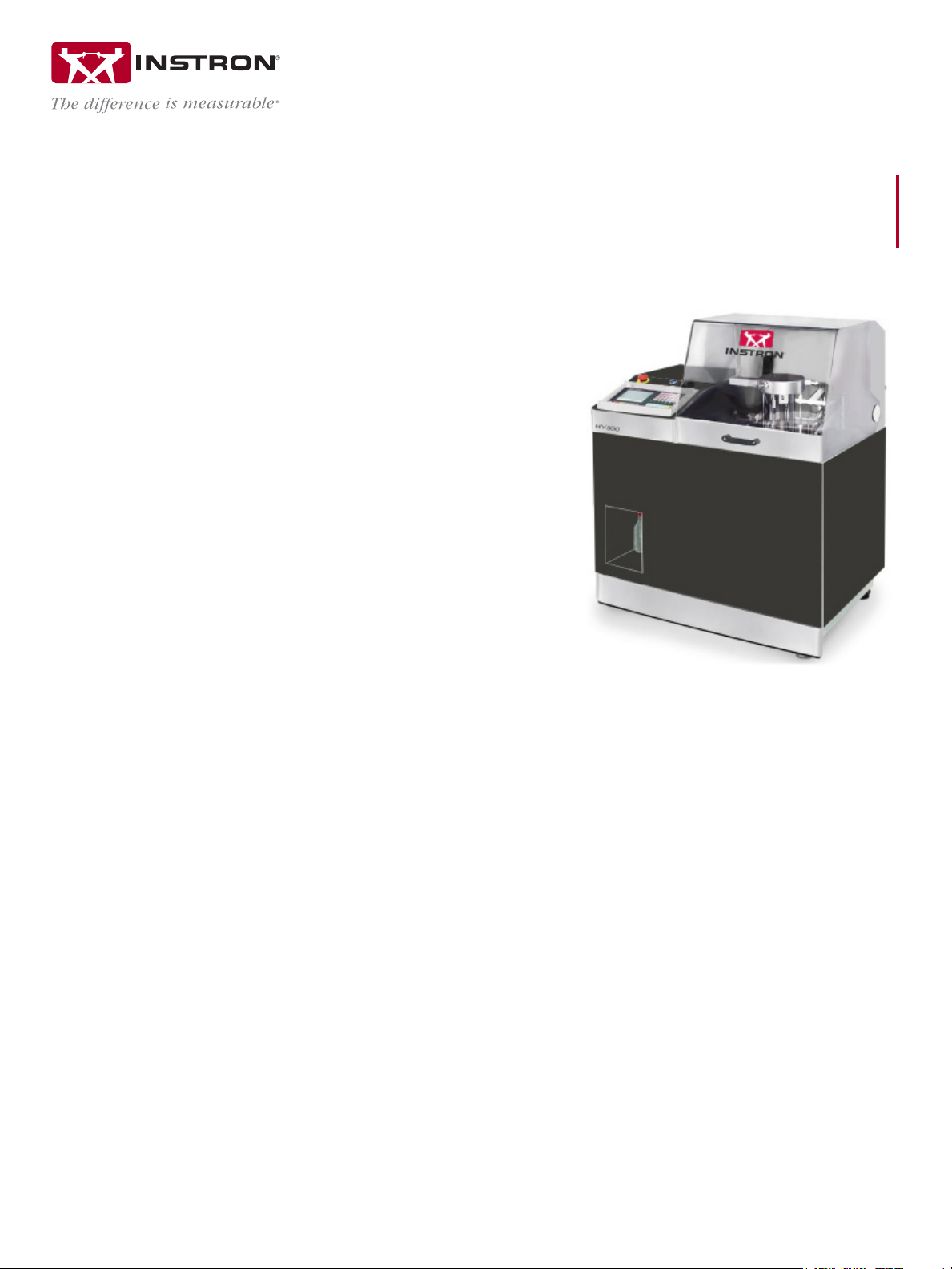

HV 500

Oil- Free HDT & Vicat Tester

Instron

®

CEAST HV500 is the latest instrument design to perform

HDT and VICAT tests at high temperatures, up to 500°C, making this

instrument ideal for research and quality control applications as it is

ensuring the capability to test the new generations of techno-polymers,

characterized by their excellent properties at high temperature.

PRINCIPLE OF OPERATION

The effect of temperature on the mechanical properties of plastic

materials has a fundamental role in the design of components,

especially in the selection of materials. Unlike metals and ceramics,

plastics are extremely sensitive to the slightest changes in temperature.

The selection of plastics for applications under different temperatures

is a complex task. The material must be able to support a stress under

operating conditions without losing its strength and without critical

distortion. The effect of temperature on geometrical stability and

mechanical properties in general can be studied following different

procedures and methods like at constant temperature or with a

temperature ramp. From very simple units for QC labs to more advanced

and automated systems, the HV Series is designed to measure the heat

deection temperature (HDT) and the Vicat softening temperature (VST)

according to the related ISO and ASTM international standards. Part of

this testing application systems is the innovative CEAST HV500 tester

using the Aluminum Oxide micrometer-sized powder heating system.

FEATURES AND BENEFITS

01

• Performs HDT and Vicat tests at temperatures up to 500°C on three independent test stations.

• Eliminates all of the environmental concerns associated with silicone oil usage, such as oil vapour emissions from the

bath and the oil recycling problems.

• Innovative heating system using the Aluminum Oxide micrometer-sized powder uidized by means of compressed air.

• A very advanced air-system controller system allows an automatic regulation of the air ow as a function of the bath

temperature in order to obtain optimum temperature uniformity.

• All three stations are automatically raised and lowered by a pneumatic system at the beginning and end of test. An

independentpneumatic system applies the selected weights on the specimens and then removes them at test end.

• The instrument can be managed either through the alphanumeric keyboard or a separate PC and controlled by means of

a dedicated software.

• Maximum temperature control via rmware and separate dedicated safety thermostat. The new safety system does not

permit the opening of the new Plexiglas cover until the bath temperature has reached the threshold temperature. A safety

pressure switch is able to switch-off the heating resi.