herunterladen

© Semiconductor Components Industries, LLC, 2008

December, 2016 − Rev. 2

1 Publication Order Number:

AND8308/D

AND8308/D

Interpretation of Datasheet

Parameters for ESD

Devices

Introduction

Electrostatic Discharge (ESD) protection devices play an

important role in protecting electronic products from surges

and ESD events. The selection of the proper ESD device for

a given application requires an understanding of both the

system that needs protection as well as an understanding of

the properties of the ESD diode. The ESD device must not

disrupt the functionality of the system it is protecting during

normal operation but also must react quickly to shunt

dangerous current and voltage spikes to ground during surge

and ESD events.

This application note will define the parameters that can

be found on ESD/TVS protection diodes’ datasheets and

explain the relevance of each parameter.

DC Parameters

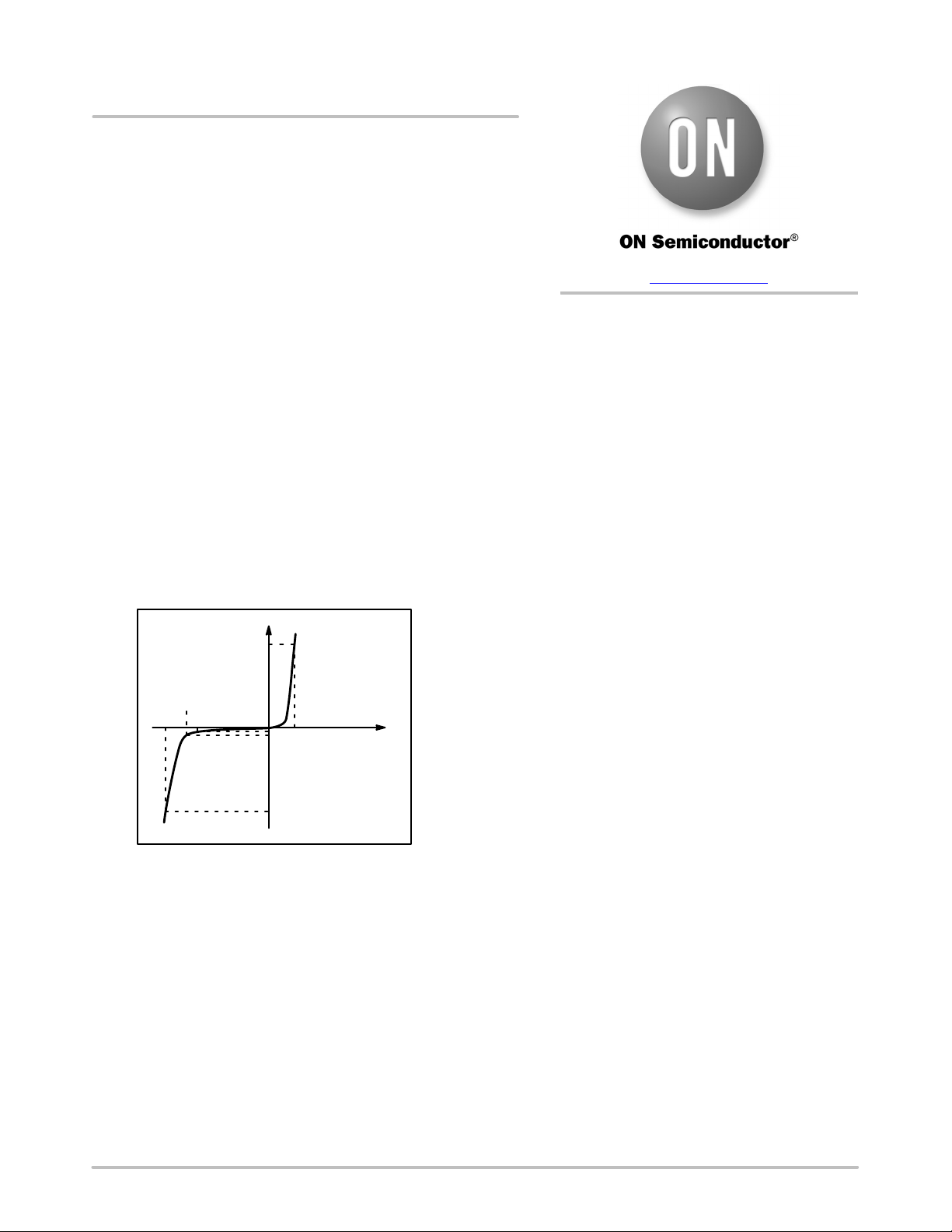

The key DC parameters of an ESD diode are presented

below. A typical IV characteristic curve for a unidirectional

ESD diode is shown in Figure 1.

Figure 1. Unidirectional IV Characteristic Curve

of an ESD and TVS

V

BR

= Breakdown Voltage @ I

T

V

RWM

= Reverse Working Voltage

@ I

R

(V

RWM

(typ) = 0.8 x V

BR

)

I

T

= Test Current

I

PP

= Maximum Reverse

Peak Pulse Current (Typically

Specified with either the

8x20 ms or 10x1000 ms Surge

Pulse)

V

C

= Clamping Voltage @ I

PP

V

C

V

BR

V

RWM

V

I

I

PP

I

T

I

R

Reverse Working Voltage, V

RWM

: Maximum nominal

working voltage for which the ESD device is intended for

use. At this voltage, the ESD diode will appear in the “off”

state as a high impedance element that will have very low

leakage current. The V

RWM

is below the reverse breakdown

voltage, V

BR

.

Reverse Breakdown Voltage, V

BR

: At this voltage, the

ESD diode starts to conduct, or turn “on”. The breakdown

is measured at a test current, I

T

, typically from 1mA to

10 mA. V

BR

is specified as a minimum value for ESD

applications and usually is 10% to 15% above the V

RWM

.

When selecting an ESD protection diode a designer must

ensure that this voltage is higher than the maximum working

voltage of the system it is protecting.

Forward Voltage, V

F

: Voltage in the forward direction at

the test current, I

F

.

Capacitance, C: Capacitance is a parameter that becomes

a concern for applications that operate at high data rates.

High capacitance will degrade signals, compromising high

speed applications. A device with low capacitance is

preferred for high speed applications. HDMI and USB

connections are examples of high speed applications where

low capacitance is needed.

ESD and Surge Parameters

Interpretation of clamping specs during ESD or transient

events is commonly misunderstood on ESD protection

datasheets. There is no industry recognized standard for

specifying clamping performance of ESD protection diodes

and it is highly dependant on the testing conditions and input

waveforms.

Survivability Specs

Peak Pulse Current, I

PP

: Maximum surge current which

the device can withstand without damage. Most low power

TVS diodes are specified with the 8 ms x 20 ms current surge

pulse. Higher power TVS diodes are measured with the

10 ms x 1000 ms current surge pulse. See Figures 2 and 3 for

definitions of these waveforms. This parameter plays an

important role to determine the robustness for high power

transient voltage suppression (TVS) applications such as

lightning or inductive switching applications, but is not as

crucial for applications that are predominantly concerned

with ESD events such as portables applications.

APPLICATION NOTE

www.onsemi.com

Verzeichnis