herunterladen

Application Note 89

AN89-1

A Thermoelectric Cooler Temperature Controller

for Fiber Optic Lasers

Climatic Pampering for Temperamental Lasers

Jim Williams

April 2001

, LTC and LT are registered trademarks of Linear Technology Corporation.

INTRODUCTION

Continued demands for increased bandwidth have re-

sulted in deployment of fiber optic-based networks. The

fiber optic lines, driven by solid state lasers, are capable of

very high information density. Highly packed data schemes

such as DWDM (dense wavelength division multiplexing)

utilize multiple lasers driving a fiber to obtain large multi-

channel data streams. The narrow channel spacing relies

on laser wavelength being controlled within 0.1nm (na-

nometer). Lasers are capable of this but temperature

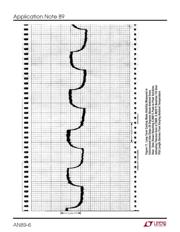

variation influences operation. Figure 1 shows that laser

output peaks sharply vs wavelength, implying that laser

wavelength must be controlled well within 0.1nm to main-

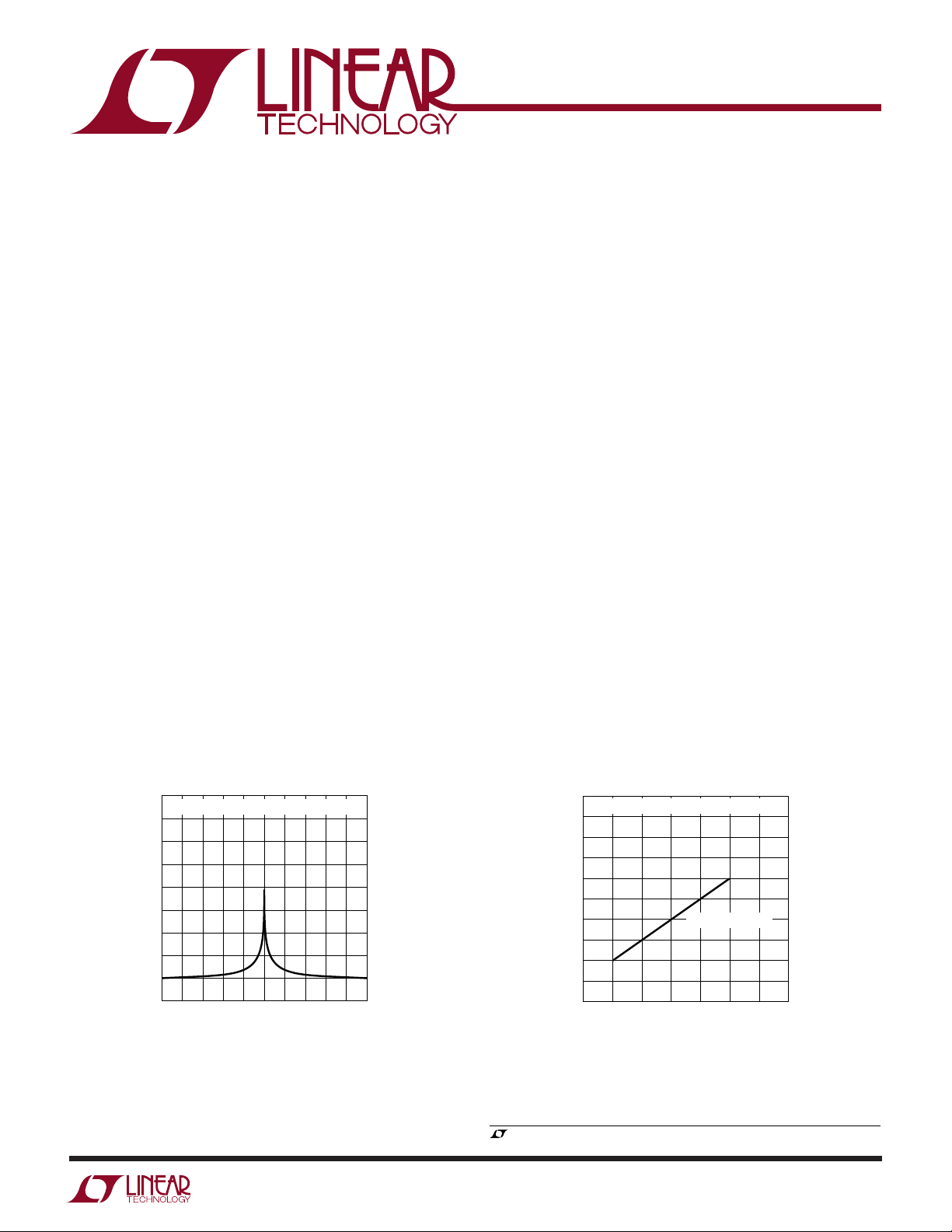

tain performance. Figure 2 plots typical laser wavelength

vs temperature. The 0.1nm/°C slope means that although

temperature facilitates tuning laser wavelength, it must

not vary once the laser has been peaked. Typically, tem-

perature control of 0.1°C is required to maintain laser

operation well within 0.1nm.

Temperature Controller Requirements

The temperature controller must meet some unusual

requirements. Most notably, because of ambient tempera-

ture variation and laser operation uncertainties, the con-

troller must be capable of either sourcing or removing heat

to maintain control. Peltier-based thermoelectric coolers

(TEC) permit this but the controller must be truly bidirec-

tional. Its heat flow control must not have dead zone or

untoward dynamics in the “hot-to-cold” transition region.

Additionally, the temperature controller must be a preci-

sion device capable of maintaining control well inside

0.1°C over time and temperature variations.

Laser based systems packaging is compact, necessitating

small solution size with efficient operation to avoid exces-

sive heat dissipation. Finally, the controller must operate

from a single, low voltage source and its (presumably

switched mode) operation must not corrupt the supply

with noise.

WAVELENGTH

(1nm/DIV, RESOLUTION = 0.1nm)

RELATIVE INTENSITY (10dB/DIV)

AN89 F01

(SOURCE: FUJITSU FLD5F10NP DATA SHEET)

LASER TEMPERATURE (°C)

10 20 30 40

WAVELENGTH (nm)

AN89 F02

1555

1554

1553

1552

1551

1550

SLOPE = 0.1nm/°C

(SOURCE: FUJITSU FLD5F10NP DATA SHEET)

Figure 1. Laser Intensity Peak Approaches

40dB within a 1nm Window

Figure 2. Laser Wavelength Varies ≈0.1nm/°C.

Typical Application Requires Wavelength Stability

within 0.1nm, Mandating Temperature Control

Verzeichnis