herunterladen

Keywords:

negative voltage, synchronous step-down converter, inverting buck-boost, factory automation, industrial process control

APPLICATION NOTE 5775

HOW TO USE THE MAX17501 AND MAX17502 FOR NEGATIVE

OUTPUT VOLTAGE APPLICATIONS

By:

Dipankar Mitra

© Apr 30, 2014, Maxim Integrated Products, Inc.

Abstract: This article shows how to produce negative output voltages from positive input voltages using the MAX17501 and MAX17502 synchronous

step-down converters.

Introduction

Industrial control equipment such as programmable logic controllers, I/O modules, mass flow controllers, and various other sensors and supporting

systems use analog components like amplifiers and multiplexers that operate on negative supply voltage. Typically operating at ±12V, ±18V or other

variations, these voltages are generated from a 24V DC bus. Maxim’s portfolio of high-voltage synchronous buck regulators offer 50% lower power

loss allowing customers to operate their equipment 50% cooler. In this application note, we discuss techniques to use these synchronous buck

regulators to generate negative voltages.

Design Considerations

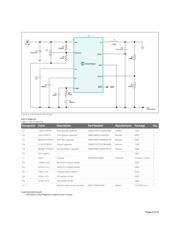

Synchronous buck converters can be configured to work in a buck-boost topology to produce negative output voltage from positive input voltage. This

application note explains how the

MAX17501 and MAX17502 synchronous step-down converters can be used to generate negative output voltage

from positive input voltage. A -15V output voltage application is used to demonstrate the principle.

Table 1. Negative Output Voltage Power-Supply Requirements

V Operating input voltage 24V ±6V

V Output voltage -15V

I Maximum output current 500mA

V Steady-state input ripple voltage 1% of nominal V

V Steady-state output ripple voltage 1% of nominal V

Operating Input Voltage Range

The sum of the maximum operating input voltage for the negative output application and the absolute value of the output voltage should not exceed

the maximum operating voltage (60V) of the MAX17501 and MAX17502, as expressed by the following equation:

V

+ |V | ² 60V

Therefore, for -15V output voltage, maximum operating input voltage can be as high as 45V. The minimum operating input voltage for the negative

output voltage application should be greater than 4.5V.

Calculating Duty Ratio

The expression for the duty ratio of the negative output power supply is shown below; ignoring the losses associated with the power switches and the

inductor DC resistance:

For the specifications listed above, the duty cycle varies between 0.45 at 18V input voltage to 0.33 at 30V input voltage. At the nominal input voltage of

24V, duty cycle is 0.38. Note that the highest duty ratio (D

) occurs at the minimum operating input voltage and the lowest duty ratio (D ) occurs

at the maximum operating input voltage (V

).

IN

OUT

OUT

IN_ripple IN

OUT_ripple OUT

IN_MAX OUT

MAX MIN

IN_MAX

Page 1 of 14

Verzeichnis

- ・ Blockdiagramm on Seite 3 Seite 4

- ・ Anwendungsbereich on Seite 1 Seite 2