herunterladen

Maxim > Design Support > Technical Documents > Application Notes > Optoelectronics > APP 3264

Maxim > Design Support > Technical Documents > Application Notes > Power-Supply Circuits > APP 3264

Maxim > Design Support > Technical Documents > Application Notes > Temperature Sensors and Thermal Management > APP 3264

Keywords: DWDM, FIber Optic, laser module, peltier, thermo electric cooler, TEC

APPLICATION NOTE 3264

Compact DWDM laser Temperature Control with the

MAX8521

Jun 27, 2004

Abstract: A complete and very compact thermal control solution for DWDM (Dense Wavelength Division

Multiplexing) laser modules can be made using a MAX8520/21 and a single op amp. Because DWDM uses

multiple lasers on a single fiber, careful control of the laser output frequencies is required. This design can

easily provide the level of performance needed for 25GHz channel spacing making it an ideal foundation for

designers working on DWDM fiber optic systems.

A complete and very compact thermal control solution for DWDM (Dense Wavelength Division Multiplexing)

laser modules can be made using a MAX8520/21 and a single op amp. Because DWDM uses multiple lasers

on a single fiber, careful control of the laser output frequencies is required. A 1548nm DWDM system with

25GHz-channel spacing requires the laser frequency to be held at the center of the 25GHz band. The laser

modules must be tuned to mid-band by changing their operating temperature and then held over all time and

environmental variations. Because the laser driver can typically change 0.1nm/°C (25GHz/°C) a temperature

controller with a stability of at least ±0.1°C is required. This keeps the modulated laser spectrum in the center

(±2.5GHz) of the band and limits channel cross talk to a minimum. Venders are promising as many as 160

channels on a single fiber.

Because the laser modules must be set to their mid-band by changing their operating temperature from 15°C

to 35°C, and the ambient can vary from 0°C to 70°C, the controller must be capable of heating and cooling.

Peltier Thermal-Electric Coolers (TECs) can perform this function but the power driver for the cooler must be

capable of bi-directional (both heating and cooling) operation. Furthermore, the driver must not exhibit dead-

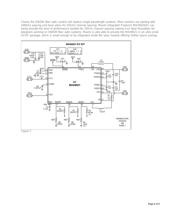

band or hunting during the transition from heating to cooling modes. The MAX8520/21 is a bi-directional power

driver capable of sourcing and sinking up to 1.5 Amps. Using the MAX8520/21 with a temperature monitor

(10kΩ thermistor) inside the laser module and a single op amp, a Proportional Integral differential (PID)

controller can be implemented as a thermal regulation loop. The circuit block is shown below in Figure 1. A

full schematic and parts list can be found at the end of this application note.

Page 1 of 8