herunterladen

Application Report

SLVA546 – January 2013

1

D-CAP2

TM

Frequency Response Model

based on frequency domain analysis of Fixed On-Time with

Bottom Detection having Ripple Injection

Author: Toshiyuki (Rick) Zaitsu, Sales and Marketing, Power Technologist, TI-Japan

Co-Author: Katsuya Goto, Takahiro Miyazaki, Digital Consumer Products, Junichi Yamamoto, Sales and

Marketing, TI-Japan

ABSTRACT

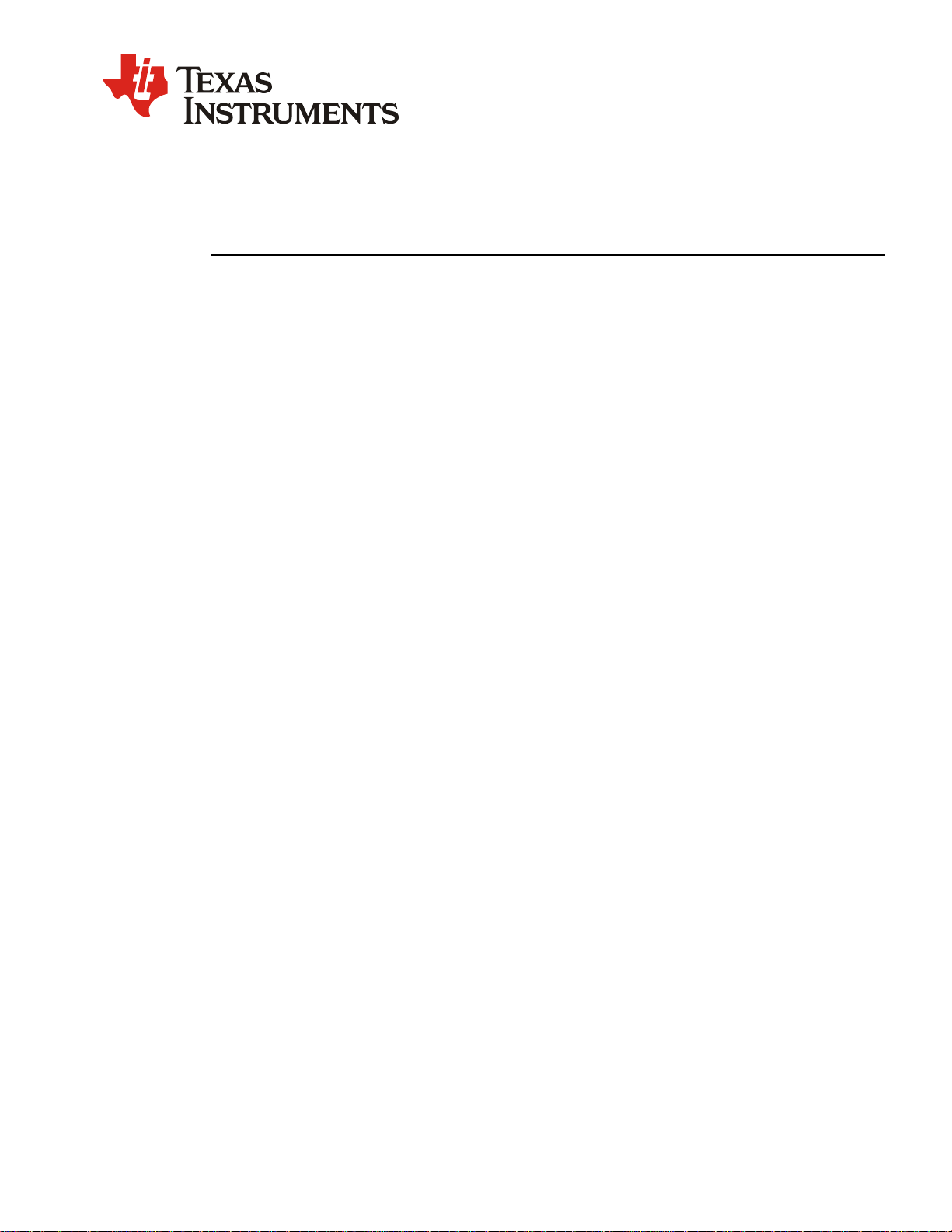

Hysteretic control [2], which is basically non-linear control, has become an important

control method due to its fast transient response. Normal hysteretic control requires a

relatively high-ESR output capacitor. Adding ripple injection to hysteretic control allows

the use of low-ESR ceramic output capacitors [3]-[6]. A “Fixed on-time with bottom

detection having a ripple injection” control topology is shown in Figure 1. This topology,

which is a type of hysteretic control, became popular due to pseudo fixed PWM frequency

operation along with compatibility with low-ESR ceramic output capacitors. It is interesting

that this control method behaves like linear control, showing similarity to a frequency

response (bode-plot) of voltage mode control while keeping wide loop bandwidth, f

bw

.

The frequency domain analysis of the “fixed on-time with bottom detection having ripple

injection” is carried out [1] for the optimal DC-DC converter design based on the

assumption of (a) Averaged model is applicable to a “small-signal analysis” for

frequencies less than the switching frequency and, (b) injected ripple voltage is small

compared to reference voltage. As a result, the comparator with ripple injection shows

single zero (1

st

order lead system) characteristics. The open loop transfer function of the

converter is expressed as equation (1). Figure 2 shows the approximated curve of the

frequency response (bode-plot) based on equation (1). The phase increases up toward

+90 degrees due to the single zero, and is a major contributor for the system stability with

wide loop bandwidth. This has advantages compared with conventional linear control

such as voltage mode control (Figure 3) or a current mode control (Figure 4). For these

linear control types, the phase curve is rolling off below 0 degrees in the high frequency

range due to the delay of

sT

e

−

of the PWM and error amplifier compensation circuit.

The operation of D-CAP2

TM

control is similar in concept with this “Fixed On-Time with

Bottom Detection having Ripple Injection”. The difference is that the ripple injection circuit

is integrated on silicon. Therefore, it is stable.