herunterladen

© 2009 Microchip Technology Inc. DS00994B-page 1

AN994

OVERVIEW

The MCP3905A/06A energy-metering Integrate

Circuits (ICs) supply active real power measurements

for single-phase residential meter designs. These

devices include features specific for the International

Electrotechnical Commission (IEC) requirements, such

as no-load threshold and start-up current. In addition,

the MCP3905A/06A Energy Meter Reference Design

demonstrates a system-level design that passes EMC

immunity requirements per the IEC standard.

EMC testing for IEC compliance was performed on the

Energy Meter Reference Design Demonstration Board

used in this application note. These tests were

performed by a third party, the results of which are

included at the end of this application note.

Accuracy tests were also performed by a third party

using the MCP3905A device across current ranges,

power factors, V

DD

and line frequency conditions

outlined in the IEC standard. The results of these tests

are also included in the "Summary".

This application note can be used for both

MCP3905A/06A stand-alone meters and PICmicro

®

microcontroller-based meters using the

MCP3905A/06A devices as the Analog Front-End

(AFE). In both meter designs, the system accuracy and

EMC immunity rely on the AFE design. Examples of

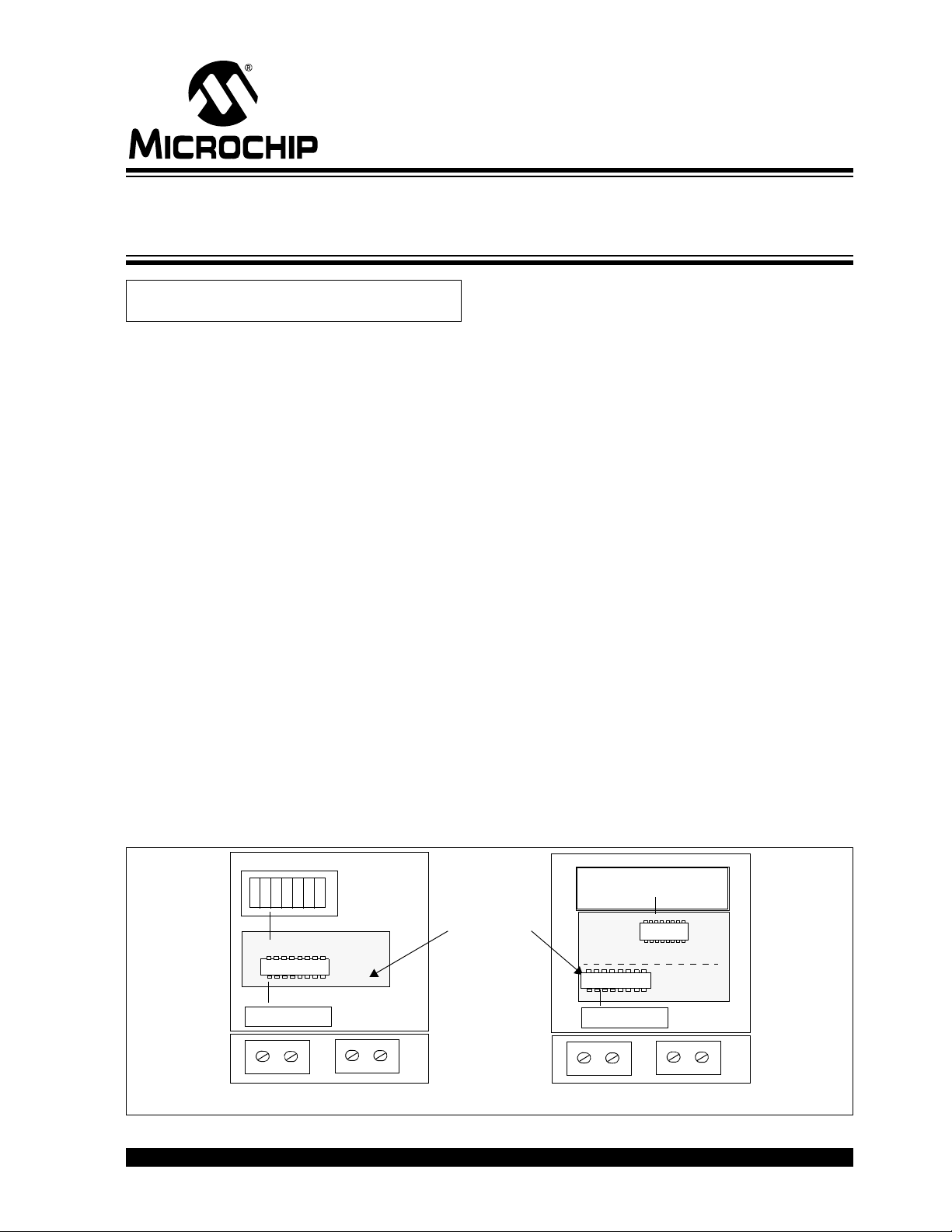

both meter types are shown in Figure 1.

GOALS

The goal of this application note is to discuss design

decisions relating to meter design when using the

MCP3905A or MCP3906A device that will lead to IEC

compliance.

Meter ratings and current sensor choices are

discussed first. The trade-off between shunts and

Current Transformers (CTs) is described, as well as

how the more accurate MCP3906A can be used as an

advantage in meter design. This application note will

focus on the shunt as a current-sensing choice and

contains sections for compensation relating to the

shunt only.

Proper selection of the PGA gain is covered, describing

how shunt sizes, power consumption goals and signals

with high crest factors guide this decision. Directions

follow that describes how to select the proper output

frequency and calibrate the meter using single-point

calibration to a typical meter constant of 100 imp/kWh

(impulses/kilowatt hour).

System-level design decisions follow, including EMC

compliance and LRC filter design. Microchip’s free

FilterLab

®

design tool is used to show anti-aliasing filter

design and phase-shift trade-offs. A spreadsheet with

complex frequency analysis is included to assist in the

compensation calculations, best showing graphically the

effects of component values in the frequency domain.

Power supply design is also discussed, including how

to choose capacitor values based on meter-specific

current requirements.

FIGURE 1: MCP3905A/06A Stand-Alone Energy Meter and Microcontroller-Based Energy Meter.

Author: Craig L. King

Microchip Technology Inc.

MCP3905A/06A

8

9

0

1

8

9

0

1

8

9

0

1

4

5

6

7

8

9

0

1

2

3

4

5

2

3

4

5

MCP3905A/06A

current-sensing

element

current-sensing

element

CLASS 1 METER 5(40)a

POWER = 1432 KW

ENERGY = 43213 kWh

28/03/2004

15:23:23

Analog

Digital

MICRO

Reference Design

MCP3905A Stand-Alone Mechanical Counter

Energy Meter

Microcontroller with LCD Energy Meter

1000 imp/kWh

CLASS 1 METER

5(40)a

MCP3905A/06A

IEC Compliant Active-Energy Meter Design

Using The MCP3905A/06A