© Semiconductor Components Industries, LLC, 2008

August, 2008 − Rev. 1

1 Publication Order Number:

AND8056/D

AND8056/D

Control Solution using Logic,

Analog Switches, and

Discrete Semiconductor

Devices for Reversing a

One-Phase Motor

INTRODUCTION

In the huge variety of the AC motors, one−phase motors

are an excellent option when only single−phase power is

available to supply electrical energy which motors require to

operate. One of the most common single−phase motors is the

split−phase motor which is used in many applications, such

as pumps, bench drills, compressors, vacuum cleaners,

electrical sewing machines, etc.

In some of these applications it is necessary to reverse the

motor which requires two conditions. The first condition is

the removal of power to the motor in order to stop it. The

second condition is to change the electrical connections

between the main and the start windings.

One of the most common methods to reverse a motor is to

use mechanical relays. This would not be a good solution for

an application in which a fast inversion of its rotation is

needed, since it would be necessary to wait about 5 seconds

before being able to change the motor rotation. Otherwise,

it will operate in the same direction due to the open function

of the centrifugal switch which remains closed until the

motor reaches a low speed.

This application note shows a possible solution to control

a 1/3 HP split−phase motor by taking advantage of different

functions performed by some devices ON Semiconductor

offers in its product portfolio. In addition, the circuit

proposed in this application note eliminates the use of the

centrifugal switch, since its function is being replaced by the

same triacs which are performing the reversing function for

the motor.

DEFINITIONS

Split−Phase Motor

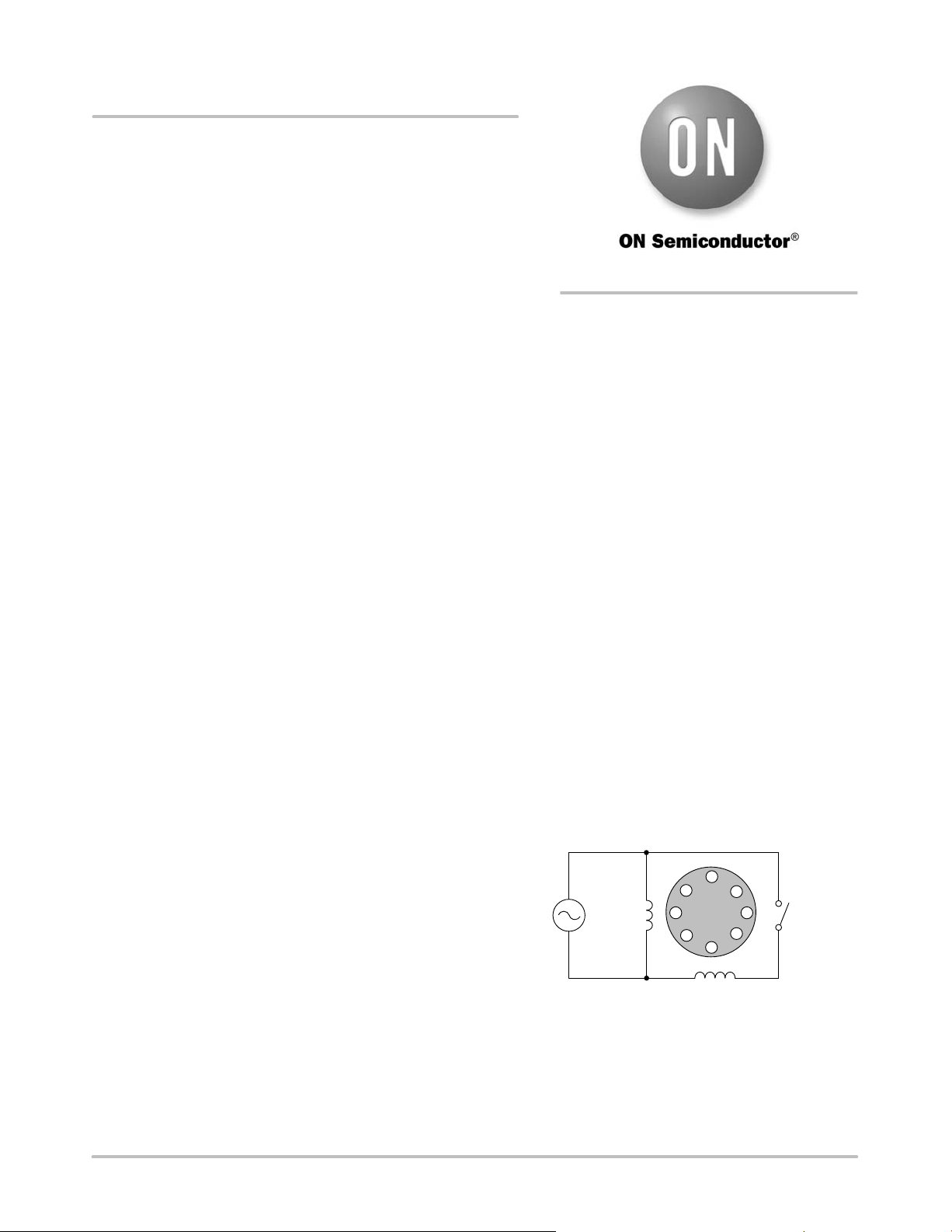

Split−phase motors have two stator windings, a main

winding and a start winding, with their axes displaced 90

electrical degrees in space. The start winding has a higher

resistance−to−reactance ratio than the main winding, so the

two currents are out of phase. Thus, the stator field first

reaches a maximum about the axis of one winding and then

later (about 80 to 85 electrical degrees), reaches a maximum

about the axis of the winding 90 electrical degrees away in

space. The result is a rotating stator field which causes the

motor to start.

At about 75 percent synchronous speed, the start winding

is cut out by a centrifugal switch. The rotational direction of

the motor is determined during its start by the initial fields

arrangement which is generated in the stator by the main and

start windings. This means, as result of the connection

illustrated in Figure 1 between both windings (M2−S1 and

M1−S2), the motor will start with a certain rotational

direction. If reverse direction is desired, the connection

between both windings must be changed as follows: M2−S2

and M1−S1. With this new connection, the fields arrange in

the stator will be changed and, as a result, the rotational

direction will be reversed. The previous statement will work

whenever the connection change is done with the centrifugal

switch closed.

Figure 1 shows a typical representation schematic for a

split−phase motor.

Main

Winding

Start

Winding

S1 S2

M2

M1

Centrifugal

Switch

110 VAC

50/60 Hz

Figure 1.

APPLICATION NOTE

http://onsemi.com

Verzeichnis

- ・ Teilenummerierungssystem on Seite 6

- ・ Blockdiagramm on Seite 3