herunterladen

© Semiconductor Components Industries, LLC, 2011

November, 2011 − Rev. 1

1 Publication Order Number:

AND8147/D

AND8147/D

An Innovative Approach to

Achieving Single Stage PFC

and Step-Down Conversion

for Distributive Systems

INTRODUCTION

In most modern PFC circuits, to lower the input current

harmonics and improve the input power factor, designers

have historically used a boost topology. The boost topology

can operate in the Continuous Conduction Mode (CCM),

Discontinuous Conduction Mode (DCM), or Critical

Conduction Mode.

Most PFC applications using the boost topology are

designed to operate over the universal input AC voltage

range (85−265 Vac), at 50 or 60 Hz, and provide a regulated

DC bus (typically 400 Vdc). In most applications, the load

can not operate from the high voltage DC bus, so a DC−DC

converter is used to provide isolation between the AC source

and load, and provide a low voltage output. The advantages

to this system configuration are low Total Harmonic

Distortion (THD), a power factor close to unity, excellent

voltage regulation, and fast transient response on the

isolated DC output. The major disadvantage of the boost

topology is that two power stages are required which lowers

the systems efficiency, increases component count, cost, and

increases the size of the power supply.

ON Semiconductor’s NCP1651 (www.onsemi.com)

offers a unique alternative for Power Factor Correction

designs, where the NCP1651 has been designed to control

a PFC circuit operating in a flyback topology. There are

several major advantages to using the flyback topology.

First, the user can create a low voltage isolated secondary

output, with a single power stage, and still achieve a low

input current distortion, and a power factor close to unity. A

second advantage, compared to the boost topology with a

DC−DC converter, is a lower component count which

reduces the size and the cost of the power supply.

Traditionally, the flyback approach has been ignored for

PFC applications because of the perceived limitations such

as high peak currents and high switch voltage ratings. This

paper will demonstrate the novel control approach

incorporated in the NCP1651 design, coupled with advances

in discrete semiconductor technology that have made the

flyback approach very feasible for a range of applications.

Controller Analysis

The NCP1651 can operate in either the Continuous or

Discontinuous mode of operation. The following analysis

will help to highlight the advantages of Continuous versus

Discontinuous mode of operation.

The table below defines a set of conditions from which the

comparison will be made between the two modes of

operation.

Table 1.

Po = 90 W

Vin = 85−265 Vrms (analyzed at 85 Vrms input)

Efficiency = 80%

Pin = 108 W

Vo = 48 Vdc

Freq = 100 kHz

Transformer turns ratio n = 4

Continuous Mode (CCM)

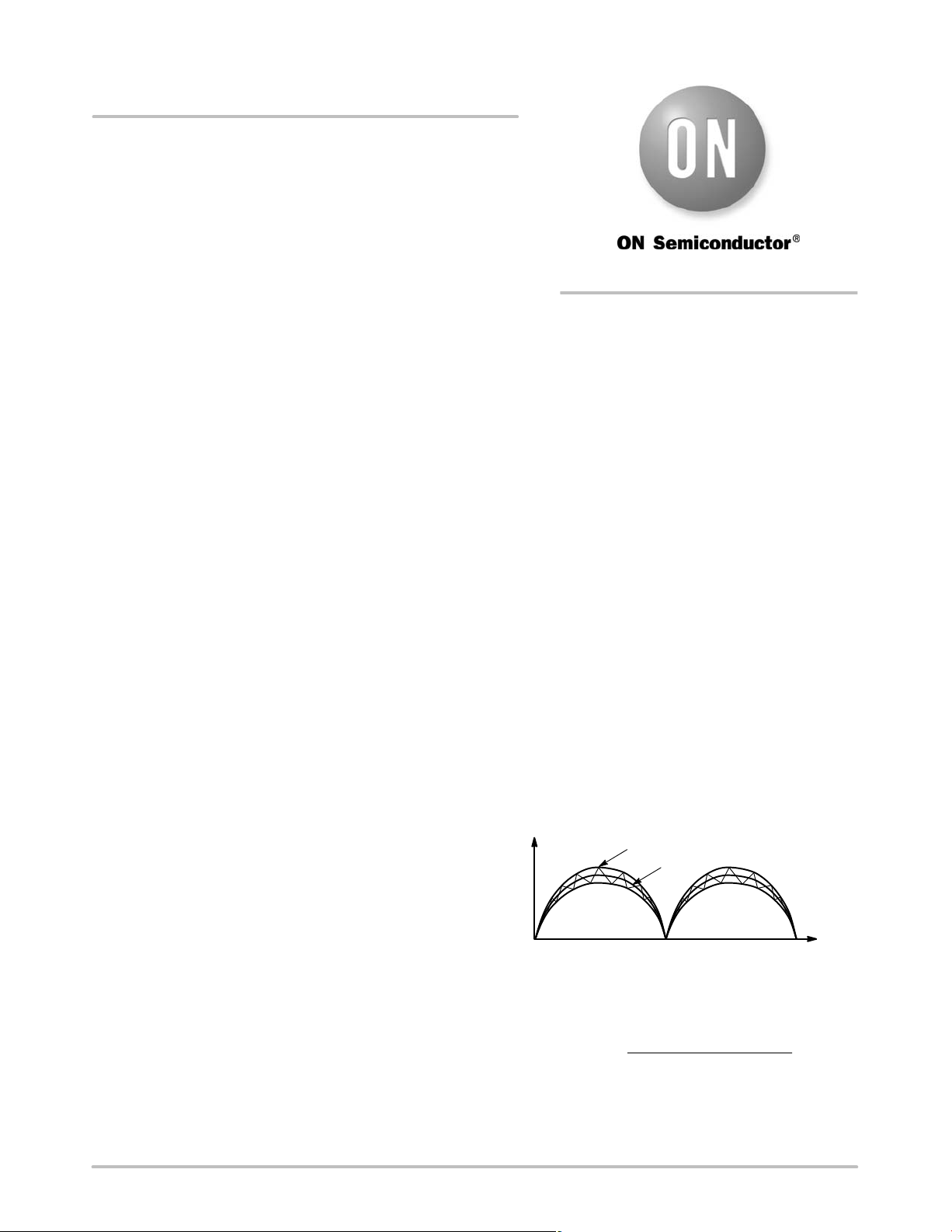

To force the inductor current to be continuous over the

majority of the input voltage range (85−265 Vac) the

primary inductance, Lp needs to be at least 1.0 mH. Figure 1

shows the typical current through the primary winding of the

flyback transformer. During the switch on period, this

current flows in the primary and during the switch off−time,

it flows in the secondary.

TIME

I

pk

I

avg

Figure 1.

Therefore, the peak current can be calculated as follows:

I

pk

+ I

avg

)

(1.414 · V

in

sin q ·t

on

·2)

L

p

(eq. 1)

http://onsemi.com

APPLICATION NOTE

Verzeichnis