herunterladen

© Semiconductor Components Industries, LLC, 2008

February, 2008 - Rev. 1

1 Publication Order Number:

AND8172/D

AND8172/D

Understanding the Noise

Issue Out of Inductor Based

DC-DC Converter

Prepared by: Michael Bairanzade

ON Semiconductor

Abstract

Portable applications, such as cellular phones and

hand-held computers, have sensitive electronic functions,

making any electromagnetic noise a real issue. Even a low

power converter can generate noise during transients since

the converters operate in the megahertz range. The high

frequency switching can interact with the parasitic circuit

elements to create uncontrolled noise. In addition, the

associated voltage spikes might be difficult to filter out, a

detailed analysis of the converter operation being necessary

to properly design the system. Of course, the mechanical

layout is a key parameter to minimize the EMI perturbation.

The main purpose of this document is to clarify the source of

such a noise, and assess the risk of system's EMI pollution.

The NCP5007 device, together with a PWM based structure,

will be used as vehicles to perform the associated

engineering test in a real application, but the same may apply

to other Boost converters, such as the NCP5005.

NCP5007/NCP5005 Basic Analysis

The NCP5007/NCP5005 are dc-dc converters dedicated

to the supply of High Efficiency White LEDs used as an

LCD back light or photo flash light source. Generally

speaking, with a typical 3.8 V Vf drop during normal

operation, these LEDs are not capable to operate from a

standard 3.6 V battery pack. A boost circuit must be

provided to raise the voltage up to the bias called by such a

diode. Moreover, these LEDs are commonly connected in

series to get a constant current through the diodes, assuring

smooth and consistent light across the LCD panel.

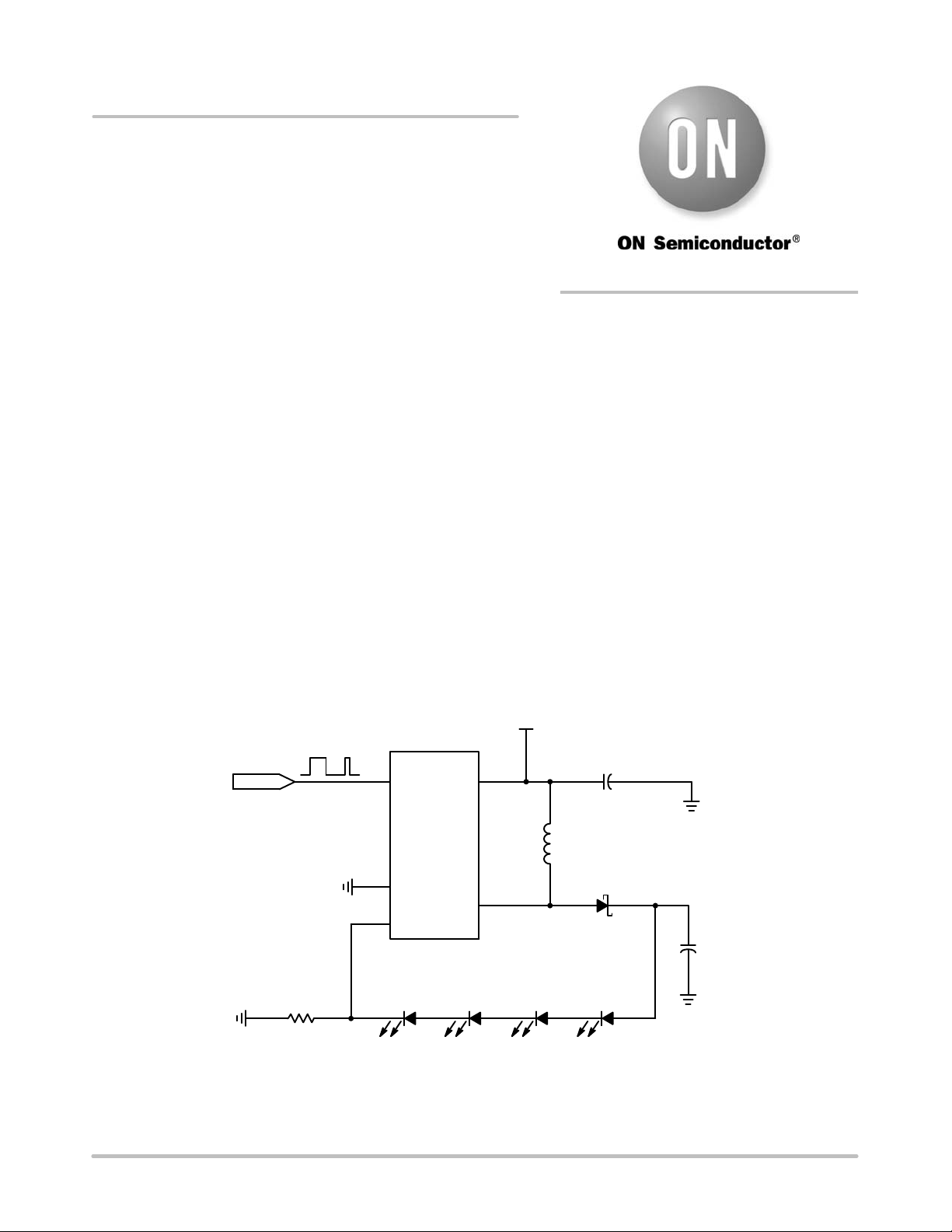

The basic application, depicted in Figure 1, drives the

back light of a standard LCD display, the command bit EN

being provided by an external CPU or other digital

controller.

EN

GND

3

U1

V

bat

5

2

GND

FB

1

V

out

4

NCP5007

47 W

R1

GND

LWT67C

D5

LWT67C

D4

LWT67C

D3

LWT67C

D2

MBR0530

D1

22 mH

L1

V

bat

C1

4.7 mF

GND

GND

C2

1.0 mF

Figure 1. Typical Back Light Application

Pulse

APPLICATION NOTE

http://onsemi.com

Verzeichnis