herunterladen

AD8450-EVALZ/ADP1972-EVALZ User Guide

UG-845

One Technology Way • P. O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Te l: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

AD8450/ADP1972 Battery Testing and Formation Evaluation Board

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Rev. 0 | Page 1 of 33

FEATURES

Fully functional Li-Ion cell formation and testing similar to

real-world manufacturing equipment

Ability to charge and discharge batteries under constant

current (CC) and constant voltage (CV) control

Energy recycling from discharging battery into dc bus

Full featured system evaluation board based on the

AD8450 and ADP1972

PC software for control and monitoring of system

parameters

Compatible with the system demonstration platform,

SDP-S (EVAL-SDP-CS1Z)

EQUIPMENT NEEDED

Bench power supply, 12 V dc (current depending on desired

battery charge rate)

Test batter y

EVALUATION KIT CONTENTS

Analog control board

Power stage board

SDP-S board for data transfer to PC

Standard USB A to Mini-B USB cable

Printed user guide

Evaluation kit software CD

Business card with Analog Devices, Inc., website address for

software and documentation

HARDWARE REQUIREMENTS

Bench power supply, 12 V dc (current depending on desired

battery charge rate)

Test battery or electronic load

PC running Windows 7

WARNING

When testing this system with lithium-ion (Li-Ion) batteries,

take care not to overcharge or overdischarge the batteries, or to

sink/source more than the maximum current recommended by

the manufacturer of the battery. Exceeding these ratings not

only damages the battery, but can also cause it to explode or

catch fire.

GENERAL DESCRIPTION

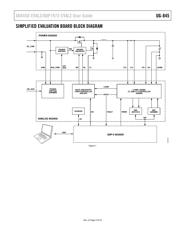

The AD8450-EVALZ/ADP1972-EVALZ evaluation kit is a good

starting point for users building battery formation and test

equipment based on the Analog Devices AD8450 precision

analog front end and controller and the ADP1972 buck or boost

pulse-width modulation (PWM) controller. The system includes

an analog control board and a power stage board.

In addition to the AD8450 and ADP1972, the analog control

board also includes an AD5689R 16-bit, precision digital-to-

analog converter (DAC) to set the current and voltage set points,

and an AD7173-8 24-bit, Σ-Δ analog-to-digital converter (ADC)

to monitor the battery voltage and current.

The board includes built-in voltage regulators so that it can be

powered either from the power stage board or directly from a

12 V dc through a screw terminal connector.

The analog control board connects to the Analog Devices

system demonstration platform—serial (SDP-S) board through

a 120-pin connector. The SDP-S board connects to the user

interface software through the USB port, allowing the user to

set the current and voltage set point as well as the mode of

operation (charge/discharge). In addition, the user can monitor

the battery voltage and current by reading the data output from

the AD7173-8.

The analog control board connects to the power stage board

through a 32-pin header. This modular approach allows the

user to design and test their own power stage boards, designed

for the current output range in their end applications, with the

analog control board of this reference design.

The power stage board supports charge and discharge currents

of up to 20 A. It includes the power MOSFETs, inductor, and

input and output capacitors required to implement a buck or

boost regulator, depending on the operating mode.

Full specifications on the ADP1972 and AD8450 are available in

the product data sheets, which should be consulted in conjunction

with this user guide when working with the evaluation kit.

The AD8451 can also be installed in the AD8450 socket with

minimal changes.