herunterladen

AN-1123

APPLICATION NOTE

One Technology Way • P. O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

Controller Area Network (CAN) Implementation Guide

by Dr. Conal Watterson

Rev. A | Page 1 of 14

INTRODUCTION

The controller area network (CAN) is a standard for distributed

communications with built-in fault handling, specified for the

physical and data link layers of the open systems interconnection

(OSI) model in ISO-11898

1, 2

. CAN has been widely adopted in

industrial and instrumentation applications and the automotive

industry due to the inherent strengths of the communication

mechanisms used by CAN.

Features of CAN include

• Allowance for multiple masters on a bus

• Inherent priority levels for messages

• Bus arbitration by message priority

• Error detection and recovery at multiple levels

• Synchronization of data timing across nodes with separate

clock sources

At the physical layer, differential data transmission is supported

by the CAN protocol, providing advantages such as

• Bidirectional communications across a single pair of

twisted cables

• Increased immunity to noise

• Wide common-mode range allowing differences in ground

potential between nodes

IMPLEMENTING A CONTROLLER AREA NETWORK

This application note considers the following aspects of how CAN

is implemented in industrial applications:

• CAN implementation layers: how the CAN specification and

protocols relate to hardware/software and CAN transceiver

products

• CAN messages: how the message structure is fundamental

to error checking/recovery and arbitration

• Arbitration: how the carrier sense multiple access method

specified by CAN allows multiple driving nodes

• Error mechanisms: how the CAN specification inherently

enhances communication robustness

• Physical bus: what measures ensure proper communication

at the physical layer

• Isolation: signal and power isolation of CAN and integrated

isolation solutions for CAN

• Stress protection: mechanisms used in CAN for protecting

transceivers from electrical overstress

HOW CAN USES DIFFERENTIAL DATA

TRANSMISSION

In traditional differential data transmission (for example, RS-485

3

),

Logic 1 is transmitted as a voltage level high on one noninverting

transmission line and low on the inverting line. Correspondingly,

Logic 0 is transmitted as low on the noninverting line and high

on the inverting line. The receiver uses the difference in voltage

between the two lines to determine the Logic 1 or Logic 0 that

was transmitted, as shown in Table 1.

A driver on the bus can also be in a third state, with the driver

outputs in a high impedance state. If all nodes are in this condition,

the bus is in an idle state. In this condition, both bus lines are

usually at a similar voltage with a small differential.

Signaling for CAN differs in that there are only two bus voltage

states; recessive (driver outputs are high impedance) and dominant

(one bus line, CANH, is high and the other, CANL, is low), with

thresholds as shown in Table 1. Transmitting nodes transmit the

dominant state for Logic 0 and the recessive state for Logic 1.

An idle CAN bus is distinguished from recessive bit transmission

simply by detection of multiple recessive bits after an end of

frame or error frame.

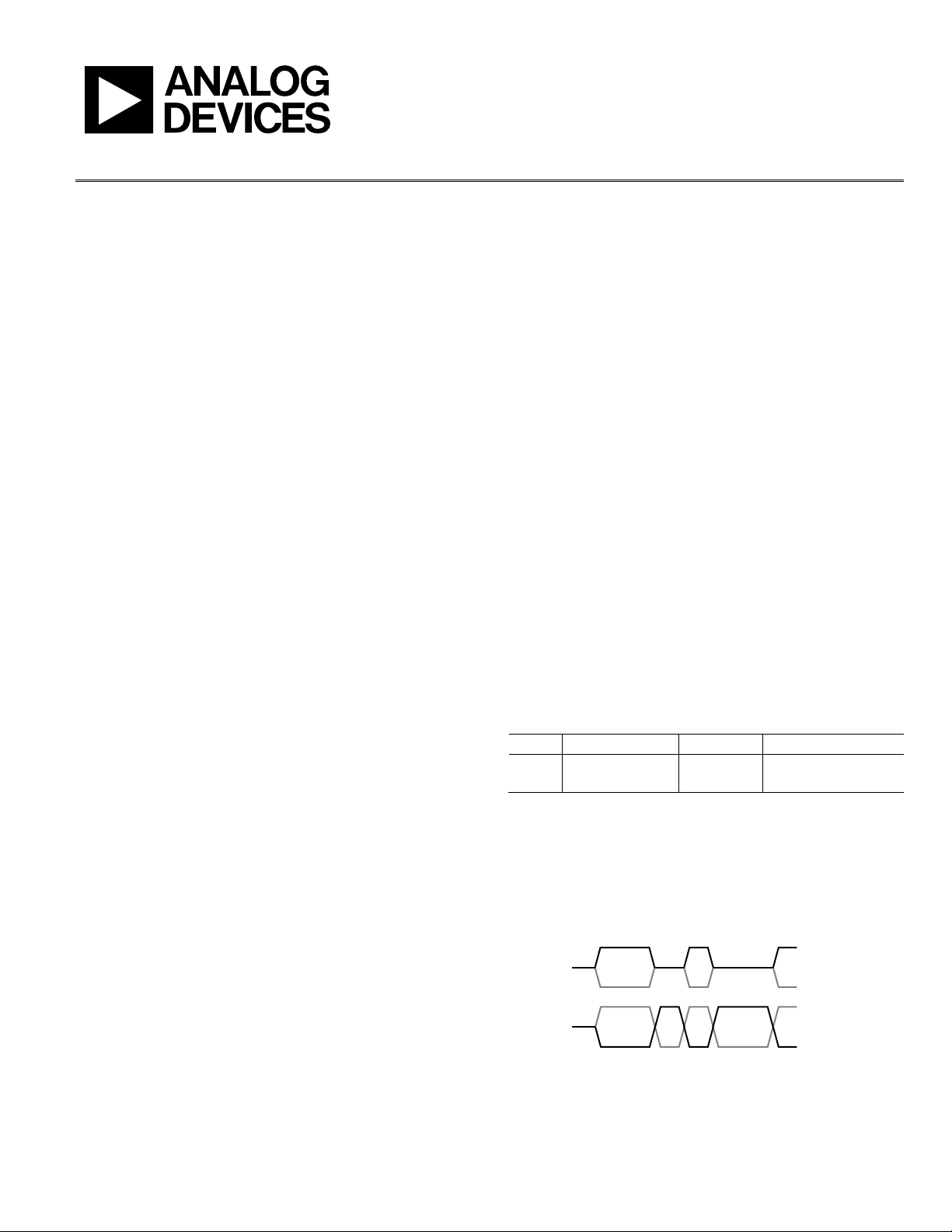

Table 1. Comparison of CAN and RS-485 Voltage Levels

Logic RS-485 Levels CAN State CAN Levels

1 A − B ≥ +200 mV Recessive CANH − CANL ≤ 0.5 V

0 A − B ≤ −200 mV Dominant CANH − CANL ≥ 0.9 V

The two states of dominant and recessive are represented by the

CANH and CANL voltage levels shown in Figure 1 that compares

CAN signaling to RS-485. This signaling method is fundamental

both to the node arbitration and inherent prioritization of messages

with lower message IDs (more initial Logic 0s as the message is

serially transmitted).

0IDLE

CAN

CANH

CANL

INVERTING

NONINVERTING

RS-485/

RS-422

0 1 11 0 0

0

(D)

IDLE

1

(R)

0

(D)

1

(R)

1

(R)

1

(R)

0

(D)

0

(D)

NOTES

1. CAN BUS IDLE AFTER MULTIPLE RECESSIVE BITS.

10035-001

F

igure 1. Comparison of Differential Signaling for CAN and RS-485/RS-422

Verzeichnis

- ・ Blockdiagramm on Seite 12

- ・ Anwendungsbereich on Seite 10