herunterladen

Atmel-8826B-SEEPROM-PCB-Mounting-Guidelines-Surface-Mount-Packages-ApplicationNote_042016

Introduction

This document provides PCB designers with a set of guidelines for successful

board mounting of Atmel

®

surface mount packages. Package Land Pattern

descriptions are depicted by the package family, and although each family is

represented by a single body size and lead count, the individual land description

apply to all packages within a particular family. Land Pattern descriptions were

provided by IPC-7351 Calculator from the Mentor Graphics Corporation. These

are only general guidelines that Atmel received from the IPC-7351 Calculator. The

solder reflow guidelines are derived from IPC -9502. Atmel does not make direct

recommendation for board design, nor does it take legal liability and responsibility

for the information in this document. Please refer to the IPC website for more

information regarding board design and processing.

1. Solder Reflow Process

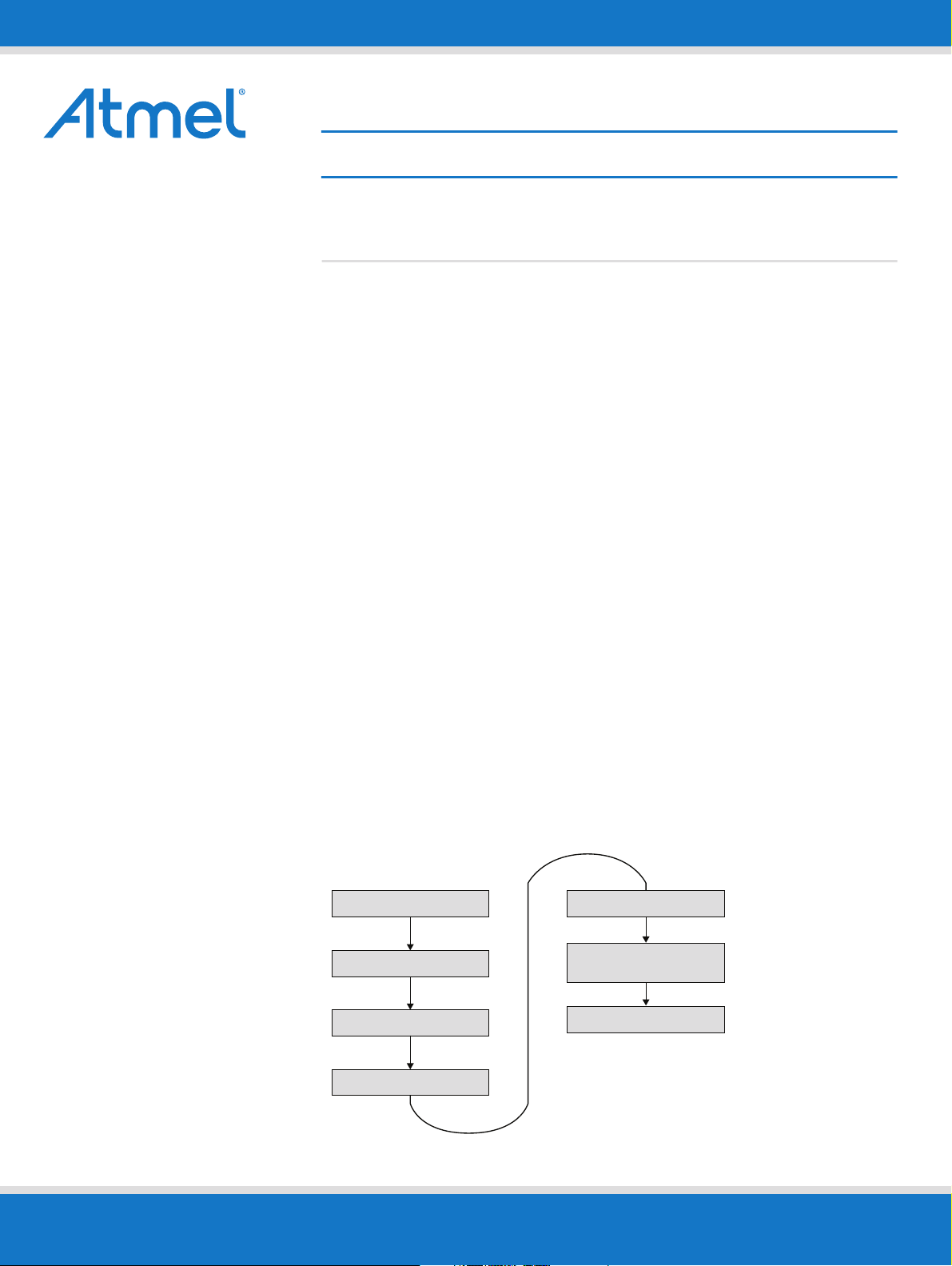

Figure 1-1 shows the typical process flow for mounting surface mount packages

to printed circuit boards. It is important to include the post print and the post reflow

inspection, especially during the process development. The volume of paste

printed should be measured either by 2D or 3D techniques. The paste volume

should be around 80% to 90% of the stencil aperture volume to indicate a good

paste release. After reflow, the mounted package should be inspected by

transmission x-ray for the presence of voids, solder balling, or other defects.

Cross-sectioning may also be required to determine the fillet shape, size, and the

joint standoff height during process development. A typical reflow profile for

no-clean solder paste is shown in Figure 1-2, temperature measured at the solder

joint.

Figure 1-1. Typical PCB Mounting Process Flow

Solder Paste Printing

Component Placement

Pre-Reflow Inspection

Reflow

Post Reflow Inspection

(Visual/X-ray)

Rework and Touch-up

Post Print Inspection

APPLICATION NOTE

PCB Mounting Guidelines for Surface Mount Packages

Verzeichnis