herunterladen

SLRA003D Aug 2014, revised July 2016 Page 1

FemtoFET™ Surface Mount Guide

Texas Instrument (TI) is facilitating the

electronics industry’s drive towards smaller

packaging outline technologies with the

FemtoFET

TM

series of packages. The

FemtoFET

TM

is a Land Grid Array (LGA)

package, which is a silicon Chip Scale

Package with metallized pads instead of

solder balls. This document describes the

Surface Mount Technology (SMT) issues

to be considered when attaching these

parts to printed circuit boards.

The FemtoFET

TM

package series is

targeted toward handheld and mobile

applications where small form factor,

space, and weight limitations

are essential.

This technology is capable of replacing

standard small signal MOSFETs, providing

a 70% reduction in footprint size. For more

information, visit: www.ti.com

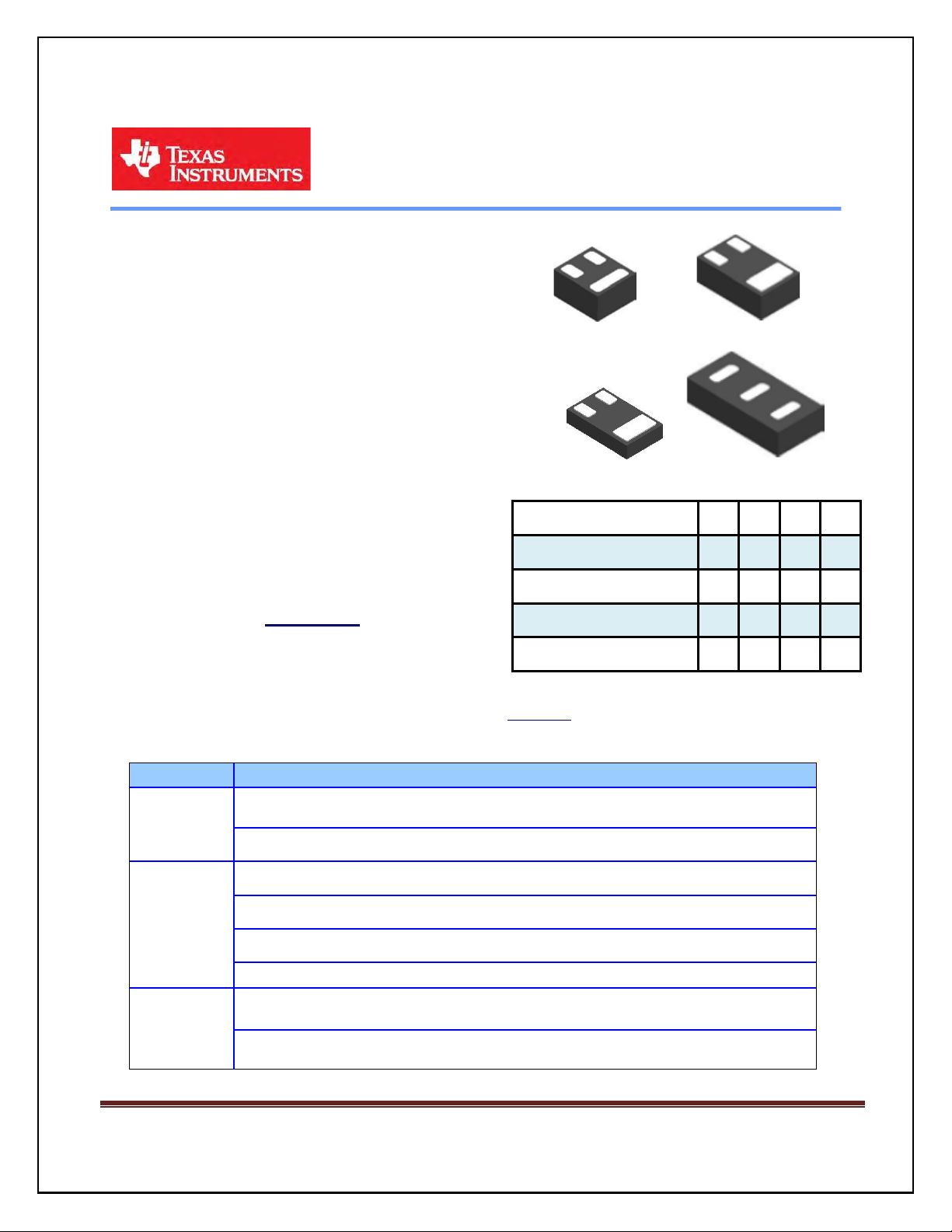

F3(YJM) F4(YJC)

F4 (YJJ) F5(YJK)

Device Name Suffix

F3 F4 F4 F5

Package Designator YJM YJC YJJ YJK

Package Width (W)* 0.60 0.60 0.60 0.73

Package Length (L)* 0.69 1.00 1.00 1.49

Package Thickness (Max) 0.35 0.35 0.20 0.35

* Nominal dimensions shown. All measurements in mm.

For additional information, see package designator at

www.ti.com

Operation Assembly Quick Start Checklist

Solder Paste

TI recommends the use of type 3 or finer solder paste when mounting the FemtoFET

TM

devices. Either no-clean or water-soluble solder paste is acceptable.

TI recommends inspection of solder paste printing quality by SPI (solder paste inspection)

machine.

Reflow

Profile

Measure the peak reflow temperature by placing a fine gauge thermocouple (Type K) on top

of the package body center.

Ensure that the peak reflow temperature does not exceed 260°C max. (260°C +0/- 5°C)

Exceeding the max temperature may damage the part.

Reflow time within 5°C Peak Temp must not exceed 20 seconds and the reflow time above

liquidus must not exceed 60 seconds.

Minimizing the number of reflow cycles seen by the FemtoFET

TM

devices is recommended.

Moisture

Handling

FemtoFET

TM

products are classified as MSL1 and require no special handling due to

moisture sensitivity. MSL1 parts are not limited by max floor exposure.

See IPC/JED

EC J-STD-033 for additional details.

Verzeichnis