herunterladen

© Semiconductor Components Industries, LLC, 2013

September, 2013 − Rev. 0

1 Publication Order Number:

EVBUM2213/D

NCS29001DGEVB

NCS29001 Evaluation Board

User'sManual

Introduction

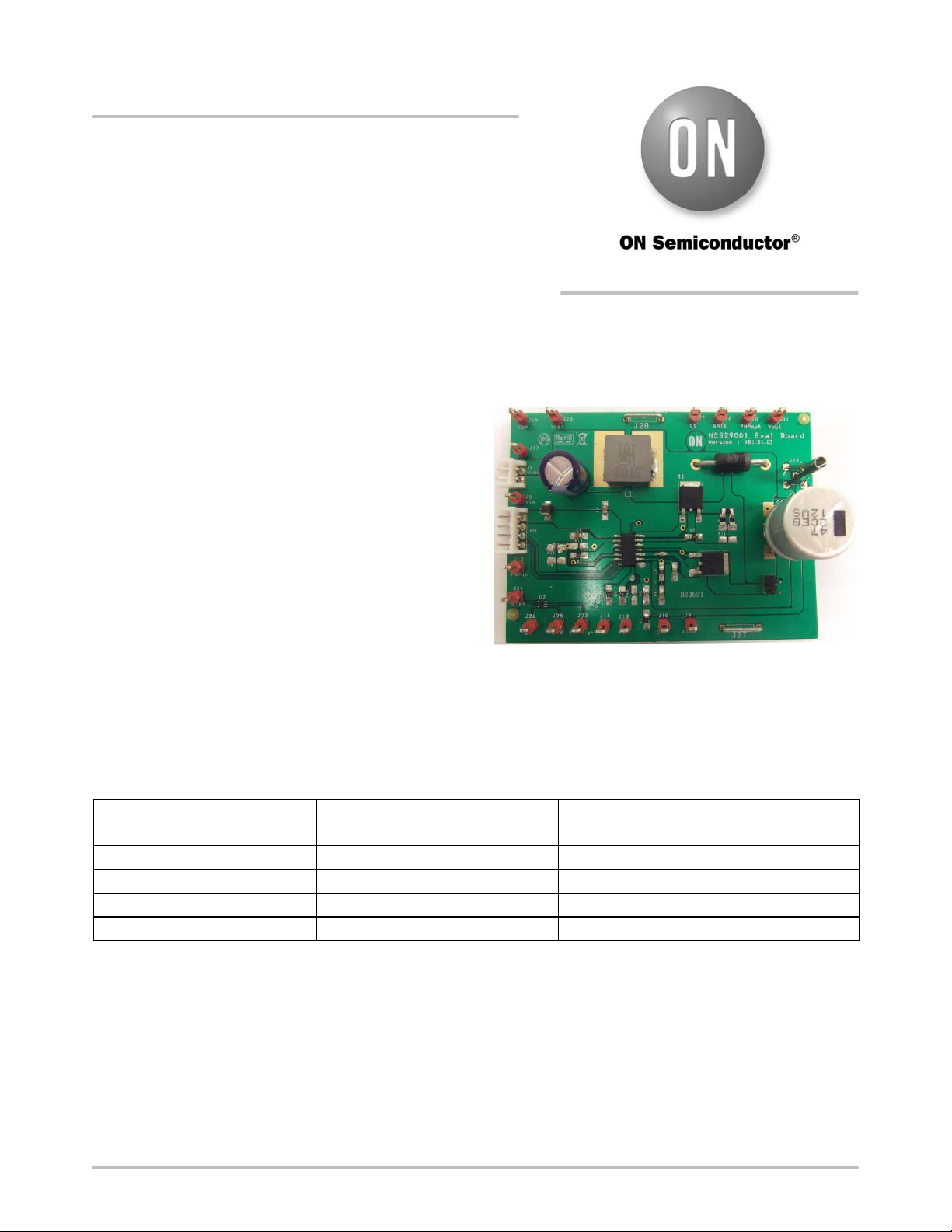

This document gives a detailed description of the

NCS29001 Evaluation Board (SOIC-14 package) with the

bill of materials, and board schematic. The appropriate lab

test setups are also provided.

The NCS29001 Evaluation Board has been designed for

a quick evaluation of the NCS29001 LCD backlight driver.

Among its main characteristics, this evaluation board has

been constructed to boost an input voltage of 24 V to drive

an output LED string of 76 V at 200 mA.

This document must be used with the NCS29001

datasheet available on www.onsemi.com. The datasheet

contains full technical details about the NCS29001

specifications and operation. The board is implemented in

two metal layers with FR-4 dielectric. The top and bottom

layers have thicknesses of 35 mm. The total PCB thickness

is 1.62 mm with dimensions of 95.4 mm by 63.5 mm.

This evaluation board can be used to evaluate the device

performance and it allows the user to place the NCS29001

device in a real application environment. While the intention

is to evaluate the device according to datasheet

specifications, it is important to take into account the

additional circuitry inherent to the setup which can affect

performance.

Figure 1. Evaluation Board (not to scale)

EQUIPMENT

The following table details the equipment used in the context of this application note manual.

Table 1. EQUIPMENT

Description Main Features Example of Equipment Qty.

Regulated Power Supply

25 V / 5 A capability or greater

Chroma 62012P−600−8

1

Multimeter

−

Agilent 34401A

1

Oscilloscope

−

Tektronix MSO2024

1

Current probe

−

Tektronix TCP202

1

Waveform generator

−

Tektronix AFG3102

1

Get Started…

• Attach output LED string (76 V total VF)

• Set VIN = 12 V and Vinductor = 24 V

• Bring device out of standby by applying high to low

transition on STBY pin

• Turn on device by applying PWM signal to PWMin pin

(between 100 Hz and 300 Hz with 10% to 100% duty

cycle)

• Turning on the device from standby will trigger

soft−start power up with smooth LED current ramp up

• LED brightness can be varied by adjusting duty cycle

on the PWM signal

• Maximum LED current is set to 200 mA for this

application

http://onsemi.com

EVAL BOARD USER’S MANUAL

Verzeichnis