herunterladen

www.DeltaPSU.com

REV.02

Instruction Manual

1. Safety Instructions

• Must select correct AC input voltage before turning on (Refer to Fig. 1).

• To ensure sufficient convection cooling, always maintain a safety distance of ≥ 20mm from all

ventilated surfaces while the device is in operation.

• The device is not recommended to be placed on low thermal conductive surface, for example,

plastics.

• Note that the enclosure of the device can become very hot depending on the ambient temperature

and load of the power supply. Do not touch the device while it is in operation or immediately after

power is turned OFF. Risk of burning!

• Do not touch the terminals while power is being supplied. Risk of electric shock.

• Prevent any foreign metal, particles or conductors to enter the device through the openings during

installation. It can cause: - Electric shock; Safety Hazard; Fire; Product failure.

• The power supply must be mounted by metal screws onto a grounded metal surface. It is also

highly recommended that the Earth terminal on the connector be connected to the grounded metal

surface.

• Warning (For Standard Terminal Block and Front Face Terminal Block products): When connecting

the device, secure Earth connection before connecting L and N. When disconnecting the device,

remove L and N connections before removing the Earth connection.

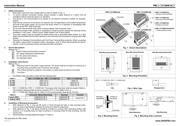

2. Device Descriptions

Refer to Fig. 1.:

1 Input & Output terminal block connector

2 DC voltage adjustment potentiometer

3 DC OK control LED (Green)

4 AC selectable switch

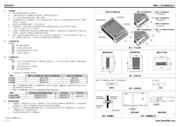

3. Installation of the Device

Refer to Fig. 2.:

A Mounting holes for the power supply (device). The device shall be mounted on minimum of 2

mounting holes using M3 screw of minimum 5mm length.

B This surface belongs to customer’s end system or panel where the device is mounted.

C Connector

• Use flexible cable (stranded or solid) with the following sizes:

Table 1:

PM☐-☐V150W1AA / PM☐-☐V150W1AG

PM☐-☐V150W1AH

12-15V

AWG 18-12

AWG 18

15-19V

AWG 20-12

AWG 20-18

19-48V

AWG 22-12

AWG 22-18

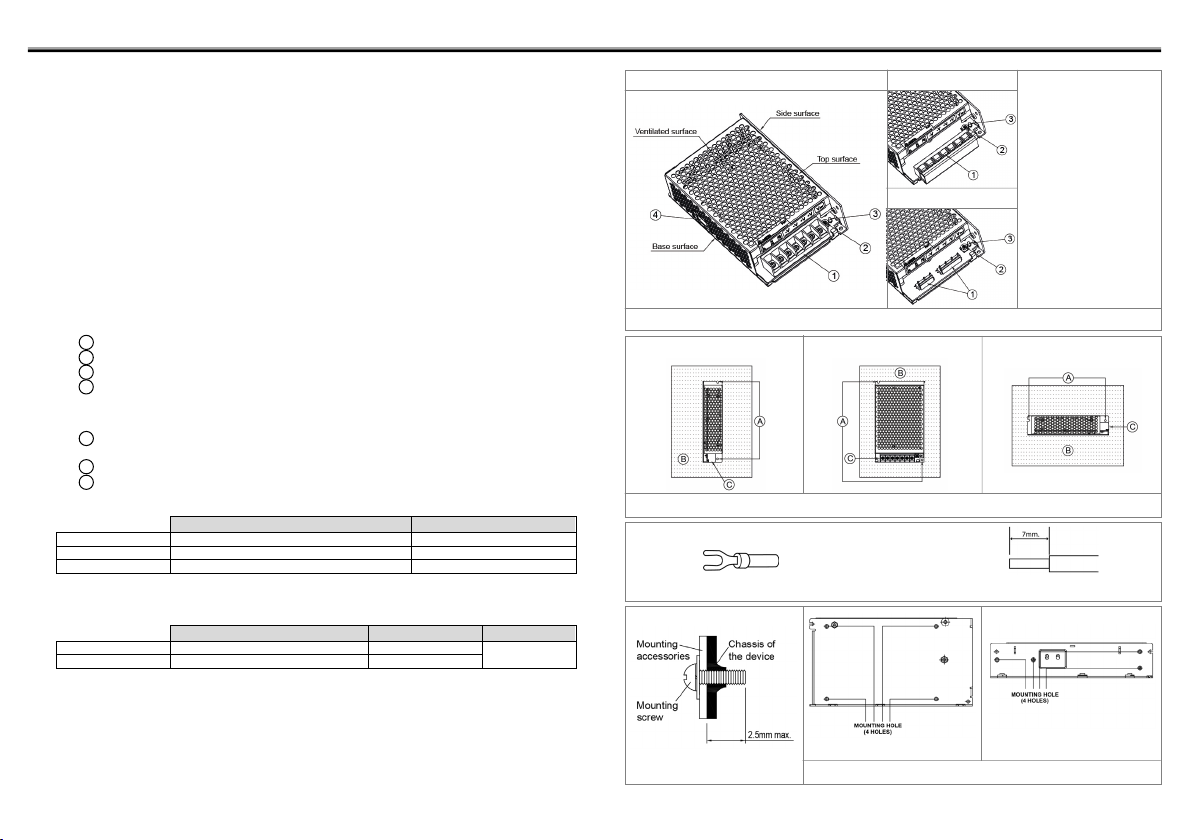

• PM☐-☐V150W1AA / PM☐-☐V150W1AG: The torque at the Connector shall not exceed 13Kgf.cm.

The insulation stripping length should not exceed 0.275” or 7mm (Refer to Fig. 3).

• PM☐-☐V150W1AH: Please refer to Table 2 for the recommended Housing and Terminal.

Table 2:

Connector (Board Mounting)

Housing

Terminal

Input (JWT)

A3963WV2-5P-A

A3963H02-5P

A3963T0P-2

Output (JWT)

A3963WV2-7P-U

A3963H02-7P

4. Installation of Mounting Accessories

• With reference to Fig. 4, only use M3 screw ≤ 2.5mm through the base or side mounting holes.

This is to keep a safe distance between the screw and internal components.

• With reference to Fig. 5, the device should be mounted on a sturdy heat conducting surface with

minimum of 4 mounting holes for base mounting or 3 mounting holes for side mounting. Use M3

screws only.

• Recommended mounting tightening torque: 4~7Kgf.cm.

PM☐-☐V150W1A☐*

Fig. 1. Device Descriptions

PMT-☐V150W1AA

PMT-☐V150W1AG

PMT-☐V150W1AH

• PMT-☐V150W1AA:

Standard Terminal Block

• PMT-

☐

V150W1AG:

Front Face Terminal Block

• PMT-

☐

V150W1AH:

Harness Connector

• PML-

☐

V150W1AA/AG/AH:

L Frame (without cover)

Side Mounting (Horizontal)

Base Mounting (Vertical)

Fig. 2. Mounting Orientation

Side Mounting (Vertical)

(PM

☐

-

☐

V150W1AA / PM

☐

-

☐

V150W1AG)

Fig. 3. Wire Type

Stripped wire

Lug

Base Mounting

Side Mounting

Fig. 4. Mounting Screw

Fig. 5. Mounting Hole Locations

*Not applicable for PMC series